You are here:

- CMP Home >

- Web Exhibits >

- GLIHC >

- 3-D & Images

- 3-D and Stereoview Images of Industrial Activity on the Great Lakes

- 1910 History Of The Iron Ore Trade

- Cleveland Press Photos

- The Great Lakes Exposition

- The Hulett Automatic Ore Unloaders Online

- Naef & Joslin Photographs: Port of Conneaut, Ohio

- Ports and Harbors Along Ohio's North Coast

- The Steamship William G. Mather

3-D and Stereoview Images of Industrial Activity on the Great Lakes

- This gallery contains 17 slides. Click on the arrows to advance to the next or previous slide.

- Click on the the photo to see the 3-D rendering.

- To view the total effect of the 3-D versions of the images use anaglyph 3-D Glasses (red/cyan).

-

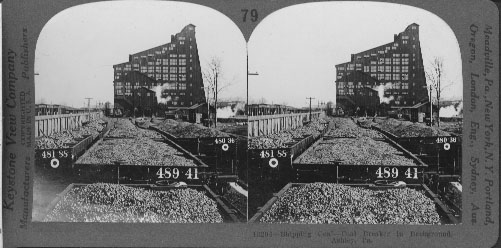

Shipping Coal —Coal Breaker in Background, Ashley, Pa.

CARLOADS OF COAL WITH BEAKER IN THE BACKGROUND, ASHLEY, PA: The big building in the background looks somewhat like a great grain elevator on the plains. It is a coal breaker. It gets its name from the fact that in this building coal is broken into usable sizes. It is necessary to break the coal because it comes from the mine in uneven lumps, some of which are very large.

A breaker is built near the mine shaft so that the small coal cars can be lifted directly from the bottom of the mine to the top of the breaker. Here the large pieces are broken, and as the coal travels downward it is sorted and sifted into its many grades. This is done in the modern breakers by machinery. If you were to ask your coal dealer about the different kinds of coal he would name them according to the size of the lumps. Rice coal is the siftings, the very small pieces. Buckwheat coal is the next size. Then come in order, pea coal, chestnut coal, stove coal, egg coal, and grate coal. There is still a larger variety known as steamboat coal, but this is too large to be burned in an ordinary furnace.

The sorting of these different kinds of coal is done by a system of screens which lie in tiers. Each succeeding screen projects farther out than the one next above it. The finest coal falls into the first row of bunkers, the next in order falls into the next row of bunkers, and so on.

As you see, switches from the railroad are connected with the breaker. The coal falls into car from chutes leading from the breaker. One of these chutes you can see at the left of the breaker building. You will observe that each car is loaded with the same size lumps. These cars carry the fuel that heats our houses, lights our cities, drives our street cars, and runs the machinery of industry.

This tonnage was estimated to be about $1,012,829,000. -

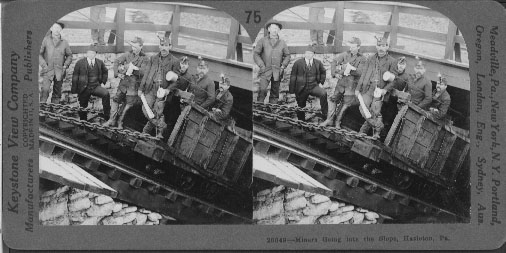

Miners Going into the Slope, Hazleton, Pa.:

You see here a crowd of miners on a car ready to be lowered into a Pennsylvania coal mine. Inside the shaft, running directly down into the earth, there is a tunnel, or slope, as it is called, leading into the mine. On cats such as the one here shown coal is brought to the surface from far back in the mine. A stationary engine furnishes the power to drag the cars up the steep incline.

The scene is rich in suggesting the life of coal miners. On top of the caps of the men are lamps, some of which are already lighted. Oil is burned in these little tin lamps. One of the miners has on rubber boots, because there may be water in certain parts of the mine. Most of the men seen here are foreigners. The overseer or "boss" of the mine is easy to find.

If you were to go with these miners you would likely find that the slope was built through a vein of coal. Sometimes, however, the vein is tapped by cutting through dirt and rock. At any rate, when the slope comes to the coal vein, it winds about in the heart of the vein. Leading off from either side of it are long tunnels in which switches have been built so that the cars can be run off to the various rooms and there loaded.

The life of these miners is not east. They are well paid, the amount they receive annually depending on the amount of coal they mine. But it is lonely work. All day long, with drill, pick, and shovel, they labor steadily. Sometimes an accident happens. Gases form in some of the mines, and these are set on fire by the lights on the miners' caps. An explosion occurs. Sometimes many miners are cut off far below ground. Rescue parties may work for days in an attempt to save their lives. -

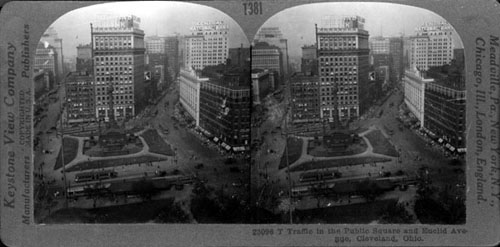

Traffic in Public Square and Euclid Avenue, Cleveland, Ohio

We are in the very heart of Cleveland, county seat of Cuyahoga County, and fifth city in size in the United State. From the Public Square before us, with its great Soldiers' and Sailors' Monument and statue of General Cleveland (sic), radiate the principal streets of the east side of the city, and to this Square converge the principal trolley lines. Here begins the famous Euclid Avenue, for some distance occupied by business houses, but farther out a handsome residential district, shaded by elms and maples and lined with palatial private homes surrounded by spacious grounds and gardens. The skyline of the business section of the city is broken by huge skyscrapers and by large department stores. The City Hall, Post Office, Chamber of Commerce and other public buildings, as well as fine hotels which provide every convenience an comfort are nearby. in the residential sections, remote from the roar of traffic, are to be found luxurious apartment houses, handsome churches, numerous parks an gardens and broads, well-lighted, attractive drives. The situation of Cleveland, on the southern shore of Lake Erie, near the iron producing regions of the Great Lakes on the one hand and the oil and coal of Pennsylvania on the other , ahas greatly favored the industrial and commercial development of the city. Some of the leading trunk lines of the railway system on the country pass through Cleveland, and there is an immense lake traffic. Many of the ore docks and lumber yards are almost hidden on the flat land bordering the Cuyahoga river, which empties into the lake. -

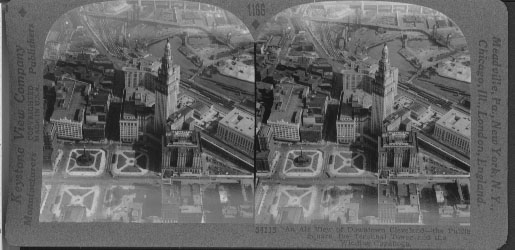

An Air View of Downtown Cleveland — the Public Square, the Terminal Tower and the Winding Cuyahoga

The Heart of Downtown Cleveland From The Air: The situation of Cleveland on the shore of Lake Erie, near the iron producing regions of the Great Lakes on the one hand and the oil and coal of Pennsylvania on the other, has greatly favored its industrial and commercial development. From an airplane fourteen hundred feet in the air we are looking down over the very heart of Cleveland. The park-like area in the immediate foreground is its famous Public Square which was laid out by Moses Cleveland (sic) in 1796. The wide street running through the center is Superior Avenue. The dominating structure in the scene beneath us is the tower of the Union Passenger Terminal, one of the finest railway terminals in the world. Here has been developed the nucleus of a small city in an area of about thirty-give acres. The Terminal Building group is a one hundred million dollar development and consists of a bank, a hotel. , a department store, a Medical Arts Building, and a Builders Exchange Building in addition to the Terminal Tower Building. The Tower soars to a height of 708 feet above e the concourse level. In the background is the Cuyahoga River that flows in winding, crooked S's through Cleveland's downtown industrial area before it finds its outlet in Lake Erie. Along the river are situated many of Cleveland's large iron and steel plants as well as many of the docks that accommodate a great share of its lake shipping. Owning to the variation in level of different parts of Cleveland there are several elevated viaducts and many bridges, nearly all municipally owned, that span the Cuyahoga River and unite the different sections of the city. Some of these are seen in the background. -

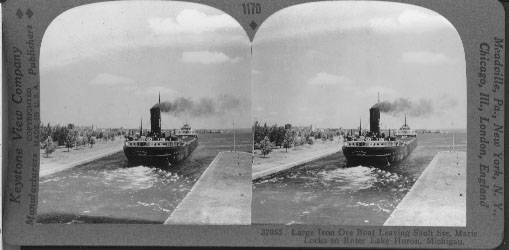

Large Iron Ore Boat Leaving Sault Ste. Marie Locks to Enter Lake Huron, Michigan

THE LOCKS AT SAULT STE. MARIE, MICHIGAN: We hear a great deal of the Suez Canal and of the Panama Canal, but there is a canal in the United States that handles more traffic than either. The Great Lakes in the United States furnish the most remarkable inland waterway in the world. To make this waterway navigable all the way from Duluth, Minnesota, to Buffalo, New York, it was necessary to do several things. The river connecting Lakes Erie and Huron had to be deepened and the connection between Lake Huron and Superior had to be negotiated in some manner.

In order to get boats through from Lake Superior to Lake Huron a canal had to be built around the rapids of St. Mary's Falls Ship Canal, popularly called the "Soo Canal." More tonnage passes through it yearly than through any canal in the world. This canal is 1 1/2 miles long and deep enough to carry the largest lake boats. One of the locks alone is 1,350 feet long and will carry boats that draw 24 1/2 feet of water.

Boats laden with iron ore from Superior, grain from Duluth, or coal from the Pittsburgh district all pass through this waterway. The odd looking freighter entering Lake Huron is well adapted to carrying ore or coal on the lakes. It is like a huge iron box with a flat bottom. There is a little house at each end. In one the crew lives. In the other is machinery. Some of these boats carry 10,000 tons of freight at one time. In 1939 more than 69,850,000 tons of freight went through the canal. The value of this tonnage was estimated to be about $1,012,829,000. -

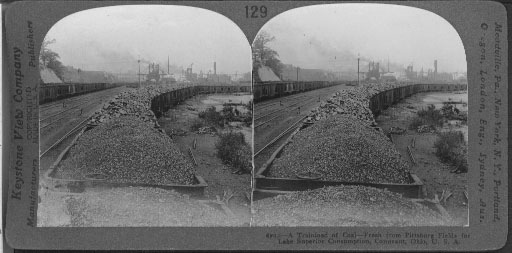

A Trainload of Coal from Pittsburgh Fields for Lake Superior Consumption, Conneaut, Ohio

There is nothing unusual about this scene. On almost any of the great railways in the eastern and middle western sections of our country such trainloads of coal as this can be seen any day. But there is a particular interest connected with this and similar trainloads of coal running from the Pittsburgh district to the Great Lakes. Our greatest iron ore deposit lies at the western end of Lake Superior. In this district, however, there are no coal fields. One of the two things must be done. Either coal must be taken to the ore fields, or the iron must be brought to the coal fields. Coal is needed to heat the iron so that it can be made into steel. When the Lake Superior iron district was first worked, all the ore was carried by huge lake boats to the coal district. But by this method, theses boats had to return empty. This was a great waste. Now the shipping is carried forward both ways. Iron and steel refineries have been built in the Superior District. The vessels that bring iron ore east, carry back heavy cargos of coal to be used in the Superior iron district. This trainload of coal that you see will be put on board one of these ships and unloaded at Duluth or Superior, not far distant from the iron ore area. This make the ports along the southern shore of Lake Erie the natural exchange place of coal and iron. Among these important ports are Buffalo, Erie, Cleveland, Toledo, Ashtabula, Lorain, and Conneaut, the city here shown. Locate each of these cities on your map. Trace a shipment of coal from Conneaut to Duluth. Through what waters does it pass? Lat. 42 N.; Long. 81 W. -

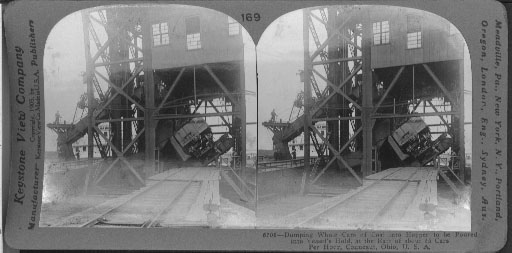

Dumping Whole Cars of Coal into a Hopper to be Poured into Vessel's Hold, Conneaut, Ohio.

This picture shows you how coal is quickly and easily transferred from the railroad cars to the ship's hold. The car which you see on the dock is held by great clamps to the platform. Then the platform, with the car fastened to it, is raised and tipped so that all the coal pours out into a hopper. Other machinery then moves the coal from the hopper to the ship's hold.

The dock in the view is at Conneaut, Ohio. Conneaut is one of the ports along the southern shore of Lake Erie, which has become and exchange place for coal and iron. Our greatest iron ore deposit lies at the western end of Lake Superior. In that district, however, there are no coal fields, and coal must be had to heat the iron ore, and to furnish carbon to mix with it, so that the iron can be made into steel. One of two things must be done. Either the coal must be taken to the iron fields, or the iron must be brought to the coal fields. At first, the iron was taken to the coal fields, and empty boats returned for more ore. Now steel refineries have been built in the Superior district similar to those near the coal fields in the east, so that today the shipping is carried on both ways. The vessels that carry iron east, carry back coal to be used in the Superior district. The coal being loaded at Conneaut will be taken to Duluth or Superior not far from the iron ore area.

Buffalo, Cleveland, Toledo, Ashtabula and Lorain are other ports which have become exchange places for coal and iron. Locate these posts. -

Iron Ore Being Taken from an Open Pit Mine, Hibbing, Minn.

This steam shovel is scooping up iron ore in an open-put mine in the Mesaba Range in Minnesota. This is the most valuable iron region known in the world. Most iron is hard rock and must be blasted. It must also be mined underground. But in this unusual mountain range the iron ore is so near the surface and so soft that it can be mined with steam shovels such as you see in this picture. This shovel is cutting a trench several yards wide. It is loading the ore it removes into those cars near by. This shovel can load one of those cars in about three minutes. Each year the Mesaba Range mines furnish one-third of the world's supply of iron. The Mesaba, The Vermilion, and Cuyuna Ranges, all in northern Minnesota, enable the United States to lead the world in iron and steel industries.

At one time all the iron ore from this district was shipped to the eastern coal fields. This was economical because it takes two tons of coal to smelt every ton of ore. However, instead of allowing the ore boats to return empty they were finally used to bring back coal so that some of the smelting could be done in the iron districts.

Iron and steel, which is a form of iron, are so necessary to us today that if all iron suddenly disappeared we would have to live almost as savages do. Our tools, machinery, screws, nails, ships, engines, automobiles, car tracks, frame work for large buildings, stoves, and many other things are made wholly or partly of this important and valuable metal. -

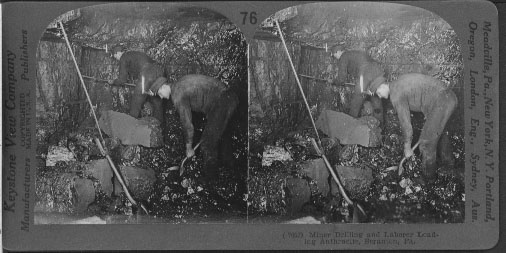

Miner Drilling and Laborer Loading Anthracite, Scranton, Pa.

Here you see a miner and his helper working in a coal mine. The miner contracts with the company to mine the coal for so much per car or per ton. He furnishes his own tools, pays for the powder with which to blast the coal loose, and hires a helper to assist him at so much a day or so much per ton.

The miner in the background is drilling a hole in the solid layers of anthracite, making ready to put in a blast of powder. The helper is busy shoveling the loose coal into a car which will carry it to the elevator. From there it will be taken to the surface where there is a coal breaker. You will observe that each man has a tin lamp fastened to the front of his cap. What looks like candles sticking up from these lamps are the sheets of flame.

This scene was taken with a flashlight, so the mine appears to be very well lighted. As a matter of fact, it is pitch dark in here. The lamps from the miners' cap make just enough light to cast queer-looking shadows in all the corners. How would you like this kind of work, far below ground in the dark?

Anthracite is the coal we call hard coal. The soft coal is called bituminous coal. The anthracite district of the United States is a small area, and Scranton is in the very heart of it. Soft coal is found in many states. Pennsylvania leads in the production of both kinds. In the United States, but little anthracite is found outside of Pennsylvania. West Virginia, Illinois, Ohio, Kentucky, Indiana, and Alabama are our most important producers of soft coal. The value of bituminous coal in the United States in 1915 was over $500,000,000. The value of the anthracite was $185,000,000. -

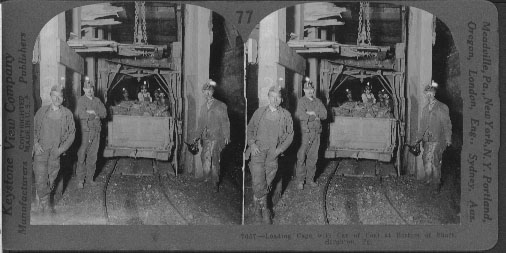

Loading Cage with Car of Coal at Bottom of Shaft, Scranton, Pa.

Here you are at the bottom of an anthracite, or hard coal mine. This is the lower end of the large shaft which leads to the surface of the earth perhaps 1,500 feet above. A carload of coal is on the elevator or cage ready to be lifted to the top of the dump into the breaker. The cage and the shaft are the center of a mine of this kind. To it lead the many switches from acres of underground rooms. It is necessary that this shaft be constructed of strong materials. For not only must all the coal be brought to the surface through it, but it is the only exit of the hundreds of miners.

You can see for yourself that the shaft and cage here shown are strongly made. You will observe the large timbers, the heavy framework of the cage, and the big safety chain above. The weight on the cage you can figure for yourself. The car weighs one ton and the coal two tons. The cage weights 1 1/2 toms and the 1500 feet of wire rope, which lifts it, another 1 1/2 tons. How much is this in all? You will be interested to know that the rope is made of strands of woven steel wire, 19 wires to the strand. It is 1 1/8 inches in diameter and can lift a weight of 60 tons. Some of the cages used in these mines have two decks, one about the other. By this means, two cars of coal can be lifted at a time.

Some of the Pennsylvania shafts are sunk 3,000 feet beneath the surface of the earth. This means that some of the coal is actually mined below sea level. In many of these deep mines it is necessary to have extensive pumping equipment to remove the inflow of water. Pennsylvania mines, however, are shallow as compared with most of those in Europe. Some of the European mines are over a mile in depth. -

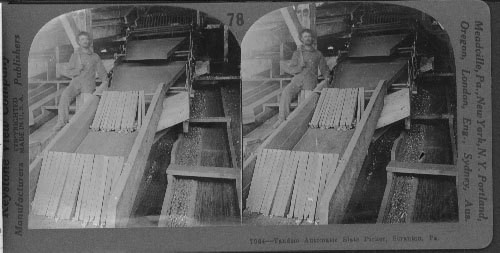

Tandem Automatic Slate Picker, Scranton, Pa.

Unless you know something of the history of coal mining, you cannot understand the value of the machine here shown. In the great breaker building the coal is first crushed. But the coal is not pure. There are minerals, especially slate, mixed with it. This must be removed before the coal is put into the cars for shipment. The labor of sorting out these pieces of slate and rock was formerly given over to boys. These were only lads of from 9 to 15 years, who sat all day long beside the small coal chute, working for a small sum of money per day. Here they sat, cramped and stooping, their little hands worn and tired, and their bodies aching.

You perhaps have heard of the term, child labor. Much has been written and said about it in the last few years. Every child should be given a chance to make the most of himself. In his youth he should be given an opportunity to learn about the things that other people do, and how they do them. Then, when he grows to manhood, he will be able to decide upon a business which he thinks he will like. The breaker boy had no chance to do this. Now laws have been passed to prevent children under a certain age, from working all day long.

Moreover, machines have been invented that make labor unnecessary in coal mining. The simple one you see here does the work of many breaker boys. As the coal slides down these chutes, the wooden jigs lift and let the lighter, fast-traveling coal pass by, but hold the heavier slate and rock. The machine is not at work, as you see it, but under each of the jigs is shown a pile of slate that had been caught. This slate is dropped into special chutes and removed from the breaker. -

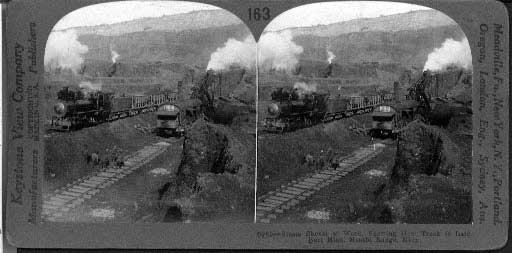

Steam Shovel at Work, Showing How Track is Laid, Burt Mine, Mesabi Range, Minn.

In many was the Mesabi Range is the most wonderful of any mountains in the world. The range is low, most of the mountains being mere hills. But a large part of these hills is made up of free iron ore. The ore, as you see, is scooped up in some places by steam shovels just as gravel is removed from pits.

In most places it is necessary to remove an overlay of several feet of clay. You can see this clay banked in the extreme background. Once the layers of ore are reached, they are removed on different levels. The steam shovel working in the foreground is cutting a trench several yards wide. The ore that it removes is dumped into ore cars that stand on tracks near by. Directly behind the steam shovel another track is being laid. As soon as the ore has been shoveled the full length of the track that is now being made, the ore cars will run on the track in the foreground.

The present Mesabi Range is the foot of an old mountain ridge worn down by glaciers. It is by far the most important iron-ore producing section in the whole world. Annually it produces almost 30,000,000 tons of ore, one-third of the supply of the world. This range, taken with Vermilion and the Cuyuna ranges, all in northern Minnesota, make the United States the leading nation of the world in the iron and steel industry. In recent years, iron smelters have sprung up in this section of Minnesota. The coal and coke needed for fuel are brought by the ore ships on their return trip from the east. But, generally speaking, it is far more profitable to take the iron ore to the coal district than to bring the coal to the iron district. -

Stripping Anthracite Coal, Penna.

When a vein of coal lies near the surface of the earth it is mined in the way shown in this picture. All the dirt on top of the coal is removed by big steam shovels, one of which you can see at work. The dirt so removed is called strippings. The machines which do this work weigh almost fifty tons and remove strips of earth about twenty-five feet wide and ten feet deep. The stripping is hauled away in small cars. Notice that more earth had been removed in the center of the view. There the vein of coal is uncovered and can be taken out from the top. All that great hill of earth on the left must be cleared away, but great as the work is, it is cheaper to do it than it is to sink shafts into the ground and do the mining underground.

By the stripping method all the coal can be mined, but in mining from shafts supports of coal must be left at certain distances apart to hold up the ceiling. Mining from shafts, sunk from the surface of the earth downward, or into the side of a hill, is the more common way of coal mining because most coal is not near enough the surface to be reached by the stripping method.

Which method of mining do you think the miners prefer?

Where are the anthracite coal mines of this country? -

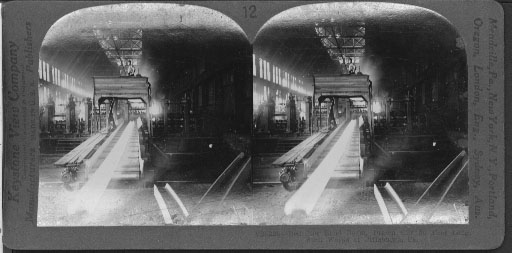

Red Hot Steel Beam, Drawn Out 90 Feet Long, Steel Works at Pittsburgh, Pa.

Pittsburgh, Pa., is the greatest steel producing city in the whole world. This picture shows a portion of the interior of one of the great steel mills. The iron is sent direct from the mine to the furnace stock pile. These are rooms in these great steel works where the iron ore and scrap iron are melted and transformed into fiery liquid. When this melted iron is drawn off it is about as thick as mild, and is called pig iron. This pig iron is the basis of all steel manufacturing. The liquid iron is then taken in huge ladles by means of electric cranes to converters or mixers. Here it is mixed with carbon of tungsten, or whatever is necessary to give the desired character to the steel. Then heavy ladles are filled with this substance and swung out over ingot moulds. The liquid steel is run into these, and freezes (way above the boiling point) into the desired shape. In the room steel rails are being made. This white, dazzling beam of metal had been rolled out to a length of about ninety feet. From this point it will be carried on rollers to a cutting platform, where it will be sawed into the proper lengths, then sent through a straightening department where the ends will be squared and the holes punched for the fishplates. It is then ready to be shipped.

The rails are loaded by a crane which is itself a huge electro-magnet. This picks up a load of steel rails as easily as a small magnet picks up a cluster of needles. -

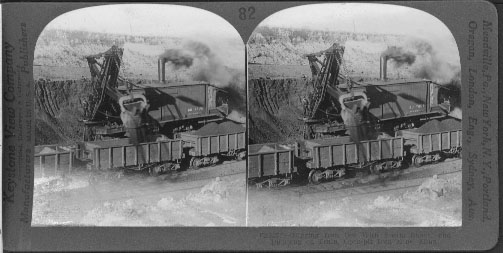

Digging Iron Ore With Steam Shovel and Dumping on Train, Open-pit Iron Mine, Minn.

OPEN-PIT IRON MINE, MINNESOTA: Iron is the most useful and most abundant of all metals. It is seldom found in its perfect natural state. It is usually combined with oxygen and other elements and found as a constituent of rocks.

Because of its iron ore, Minnesota holds an important place among the mining states of the Union. In some places the mineral is found here in almost a pure state. This picture is taken near Hibbing, in the northern part of Minnesota. It is in what is called the Lake Superior mining region, probably the largest iron producing section of the world.

Ore was first taken from it in 1884. In less than fifty years the total output of the Lake Superior mines was 192,008,000 long tons. A single mine in Minnesota has produced 1,681,000 long tons of ore in a year. The deposit is near the surface, so that mining can be carried on here on a very large scale. Sometimes the ore is dug out by steam shovels and loaded directly on the cars, as shown in this picture. A single one of these steam shovels can load two hundred cars a day, doing the work which formerly required two hundred men. Most of the ore is shipped by rail to ports on Lake Superior and Lake Michigan, great quantities going to the manufacturing centers of Pennsylvania. -

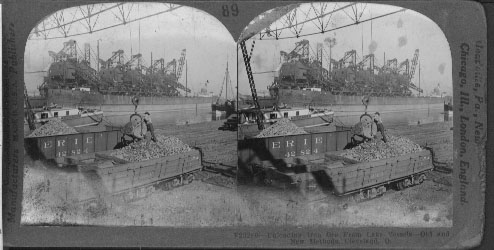

Unloading Iron Ore From Lake Vessels-Old and New Methods, Cleveland, O.

Cleveland is the largest city in the state of Ohio, and it situated on the south shore of Lake Erie at the mouth of the Cuyahoga River. It had excellent connection by water with Superior iron regions. It has a lake frontage of about fourteen miles, protected for five and three-quarter miles by a breakwater constructed by the Federal Government. The harbor has unexcelled facilities for handling iron ore. That lake steamer over yonder and the nearer vessel at our left have come down from the western end of Lake Superior, laden with ore for great steel mills at Youngstown, Pittsburg, or Wheeling.

A few years ago the unloading system which we see in operation directly before us was considered splendidly effective. That suspended bucket has been lowered into the vessel's hold and there filled, then drawn along an overhead trolley beam for dumping into the car.

Today the "clam" unloaders are more commonly used. We can see this apparatus looming in the air above that farther pier. By this newer method, five to ten tons of ore can be lifted in one load, and the work can be done much more quickly than by the "pocket" method. -

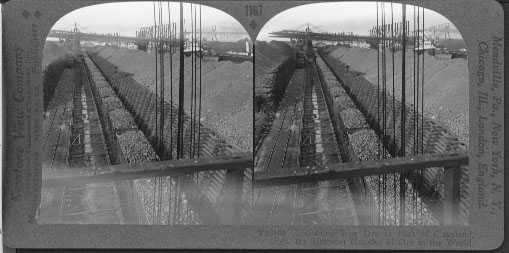

Unloading Iron Ore at Port of Cleveland, Ohio, the Heaviest handler of Ore in the World.

Iron Ore at the Port of Cleveland: Going westward from downtown Cleveland, we pass over the famous High Level Bridge and Bulkley Boulevard. In going through this part of the city sights such as this are common for many of Cleveland's ore docks and lumber yards are almost hidden on the flat land bordering the Cuyahoga River which empties into Lake Erie. A visit to Cleveland's waterfront is a fascinating adventure. Here we are looking north toward the lake. The steamers we see in the distance have come from the iron county in the vicinity of the western end of Lake Superior, where are located some of the richest iron mines in the world. To the port of Cleveland is brought over 4,000,000 tons of iron ore every year. Those long lines of piles on either side are some of this ore. Those gigantic arms in the distance that reach out over the railway tracks are part of the huge unloading machinery by which means the ore in all these piles has been taken out of the holds of the ships and dumped here. Notice the coal in the long line of freight cars. This coal is to go back to the iron county in the steamer that brought over the ore. These cars will be sent to a coal dock. As soon as the ore boat is unloaded, it will go to the coal dock and be loaded with coal. In turn the ore will be loaded into these cars after they are emptied and thus will reach the iron-manufacturing center where it will be transformed into steel. The steel eventually may reach Africa as a steel rail for a railway track, or Asia as bridge material that will span a Himalayan mountain gorge.